NEO

AUSTRIALPIN

ROCKET

AUSTRIALPIN

ROCKET

BREAKING STRENGH: 22 kN

CERTIFICATION: EN362

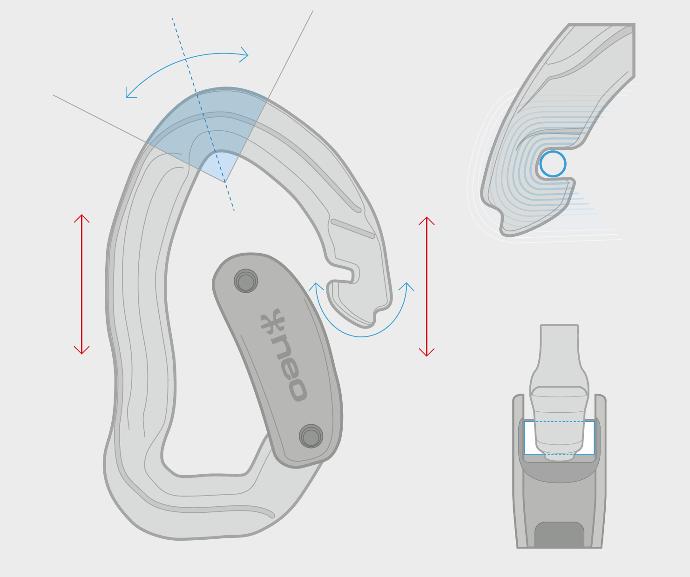

CONCEPT: automatic autolock

COLOR: red or blue

SIZE: one size

WEIGHT: 64 g

MATERIAL: aluminium

LIFETIME: replace every 5 years or 500 flight hours

MANUFACTURING: AustriAlpin Austria

THE WORLD'S SAFEST AUTOMATIC ALUMINUM CARABINER

Developed in collaboration with AustriAlpin, the NEO AUSTRIALPIN ROCKET automatic aluminium carabiner has been designed to meet the specific safety requirements of paragliding, making it the safest automatic carabiner on the market, certified to EN362. This standard requires the carabiner to be able to withstand a load of 1,500 daN when the finger is open and 2,000 daN when the finger is closed. They must be self-closing with automatic or manual locking, and must be capable of being released only by at least two deliberate and consecutive manual actions:

- Automatic lock

- Self-locking

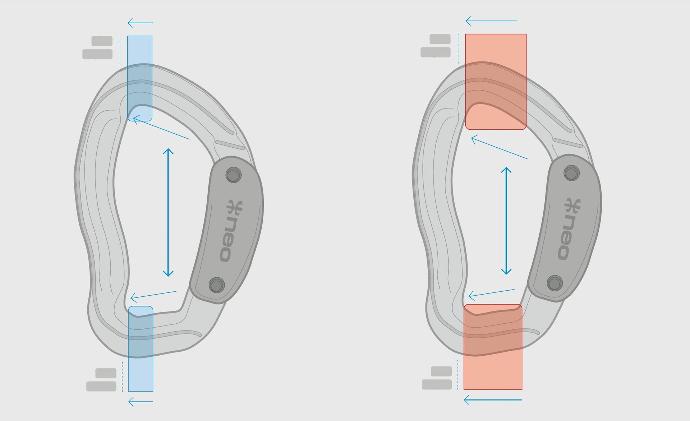

- 2 load directions.

1. FATIGUE PHENOMENON

2. WORKING AREA

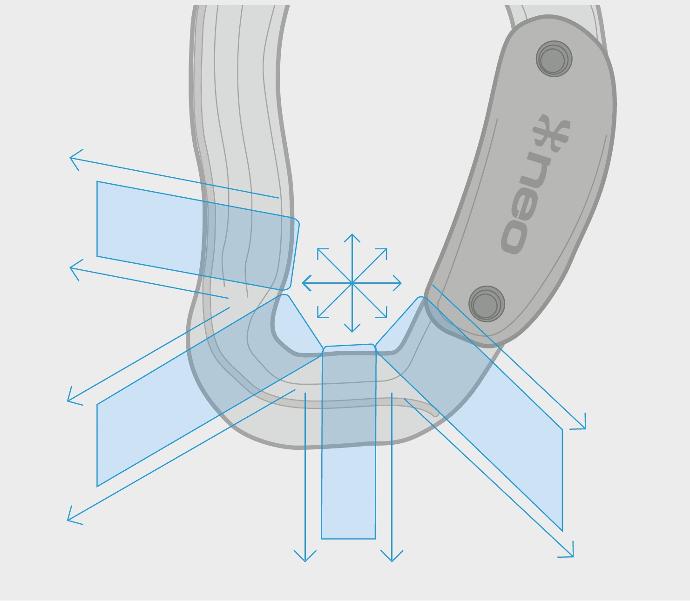

3. MULTIPLE HOOKS

Carabiners are increasingly used in paragliding because of the many different attachmentsthat are added to the main attachment points. We have developed the Rocket to increase thenumber of attachment possibilities and to secure them:

- By enlarging the lower part of the carabiner, allowing different harness straps, cockpit straps,rappels and rescue bridles to be attached ...

- Less strain on the closing finger

- Increasing the strength of the closing finger (AustriAlpin autolock system)

- By increasing the strength in both axes (22 kN / 15 kN), securing the opening of the rescueat the main attachment points