NEO X KOROYD: AN ENGINEERING PARTNERSHIP

LONG-TERM PARTNERSHIP IN PRODUCT DEVELOPMENT

Neo and Koroyd have been working together to develop safer paragliding products since 2014.

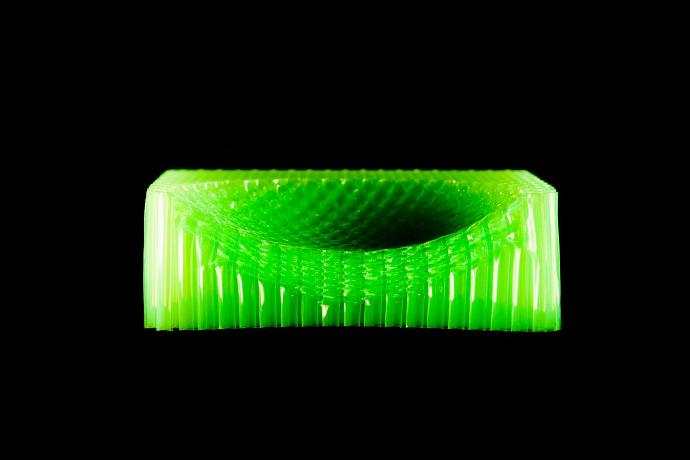

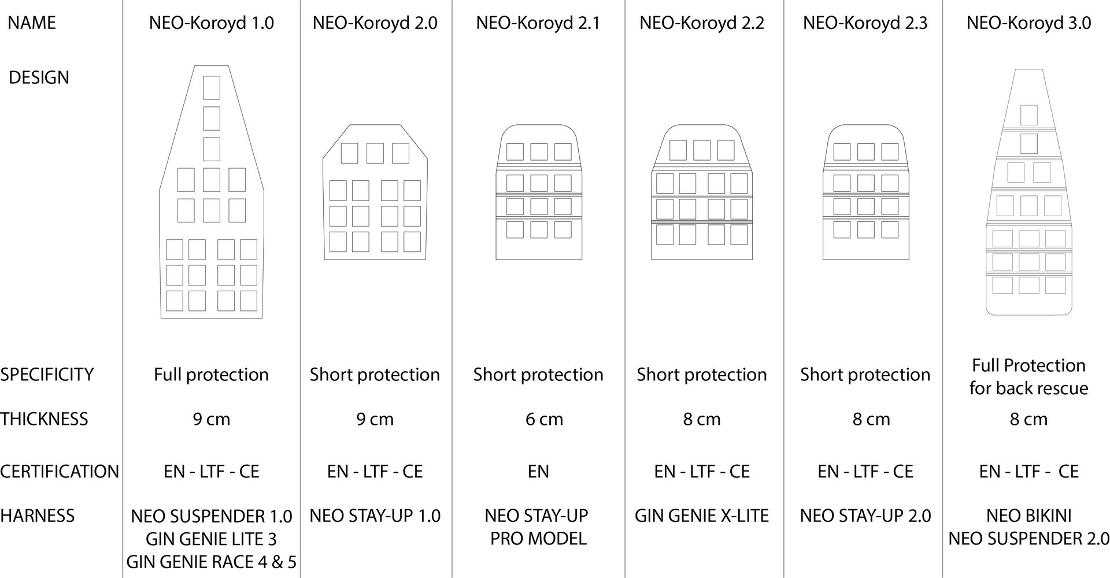

The first tests lasted two and a half years until the correct combination of Koroyd and foam was found to meet the standards and obtain the certification for paragliding. During these tests, we realized that the Koroyd technology by itself was not enough and needed to be used with a special casing. We then joined forces with Koroyd to develop a custom-shaped foam for this need. The NEO-KOROYD technology, tested and registered, was born from this collaboration.

Our common goal has always been to develop protection technology that, throughout the years, has allowed reducing the thickness, weight, and volume of protections while maintaining their shock-absorbing capacity.

ABOUT KOROYD

Koroyd has been committing to innovation for a safer future for over 10 years. Their unrelenting search for smarter, safer, and more durable protection solutions is recognized by patented and awarded innovations.

Koroyd and their team operate worldwide. Their headquarters are located at the Monaco Principality and their team is present in the United Kingdom, North America, and China. Koroyd works throughout 5 major commercial units: Sports, Motorsports, Industrial Safety, Family and Defense, and distribute their technology to clients all over the world: from the United States to South Korea.

Thanks to their expertise in various domains, they provide their partners with an in-depth expertise regarding the user's demands, R&D installations, and setup protocols to offer remarkable protection solutions.

ADVANTAGES OF NEO-KOROYD PROTECTIONS

IN PARAGLIDING HARNESSES

In terms of impact absorption:

- The energy of the impact is absorbed by the deformation of the material, noise, and heat.

- No energy restitution after the impact. Slight rebound.

- The duration of exposure to the high energy of the impact is shortened thanks to the rapid and constant deformation of the Koroyd and the absence of energy rebound.

- Full back protection.

- 100% efficient during all flight stages (take off and landing).

ADVANTAGES OF NEO-KOROYD PROTECTIONS

IN PARAGLIDING HARNESSES

- Lighter protection.

- Thinner protection for aerodynamic performance.

- Thinner protection for carrying volume.

- Stiffness for more comfort and maneuverability in flight.

HOW KOROYD WORKS

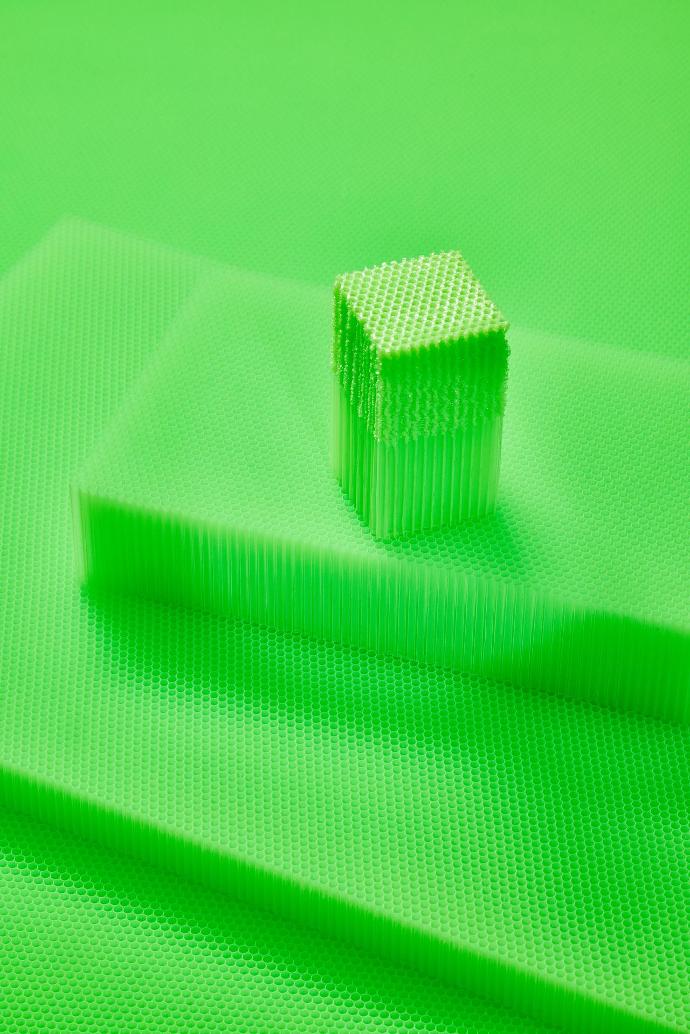

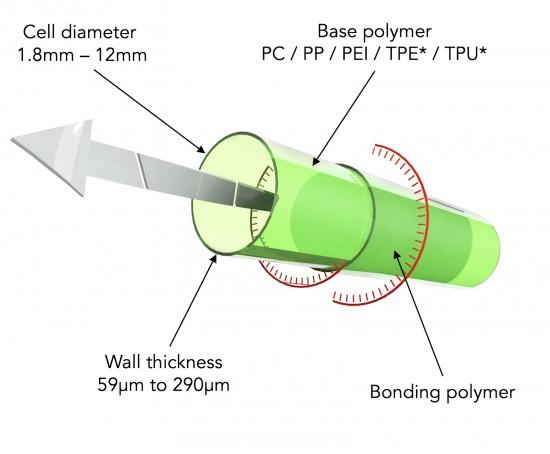

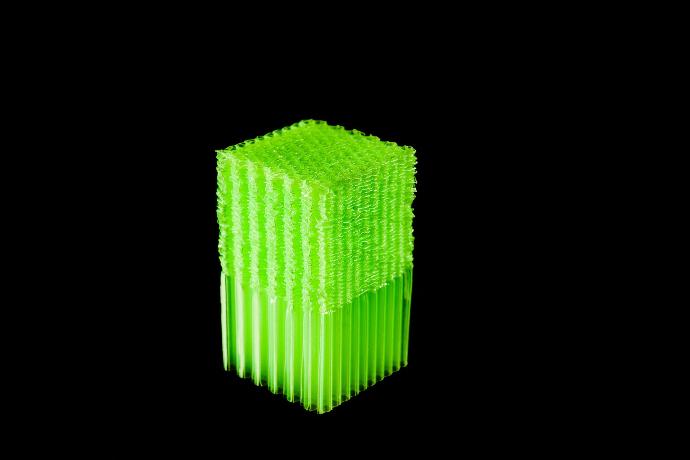

The Koroyd technology was developed from an airspace project after an aviation disaster that was widely covered by the media in the United Kingdom. The resulting material is a set of extruded and thermally welded tubes that crumple instantly and evenly during an impact, absorbing more force more reliably than any other technology.

Koroyd is a thermally welded tubular structure used in various products, from sports helmets to skis, and from industrial worker protection to car seats for children. Koroyd's main goal is to absorb energy in case of impact and protect the user against serious injuries. Besides being an industry leading energy absorber, Koroyd is also highly breathable and ultralight.

Koroyd's well-arranged structure and the tube's thin walls (59 μm à 290 μm) use a combination of controlled buckling and efficient deformation until their compression for high volumetric energy absorption.

THE PROPERTIES OF KOROYD

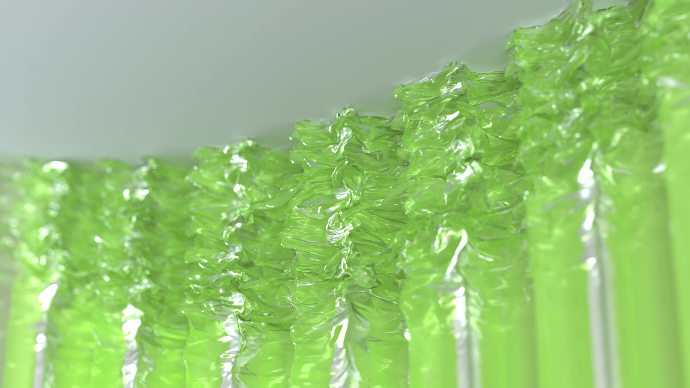

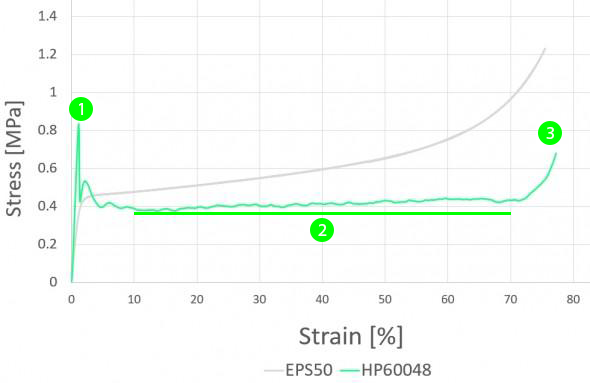

Koroyd's properties are very similar to those of an energy absorber that's ideal in compression. The mechanical properties of Koroyd are related to their deforming behavior. Unlike traditional foam (e.g. EPS), Koroyd does not harden during the compression, the stress plateau is completely flat until the densification of the material at around 70 to 80 % of compression.

This deformation is closer to the theoretical model of a mechanical energy absorber.

IMPACT ENERGY ABSORPTION

Once the initial compression of an energy-absorbing material has been released (after an impact), it regains some energy due to its elastic behavior (rebound).

MINIMUM REBOUND

Since Koroyd has less elasticity compared to traditional foam, there is less risk of a second pulse from the energy absorbed during the loading phase (less rebound).

PLASTIC DEFORMATION

With Koroyd, energy from an impact is converted to plastic deformation, a bit of heat and a bit of noise.

DESIGNING A BETTER PROTECTION FOR PARAGLIDING HARNESSES

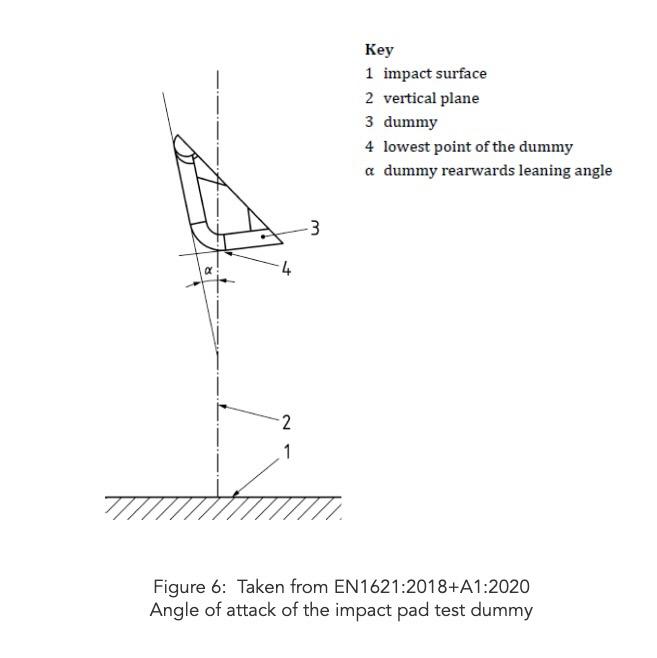

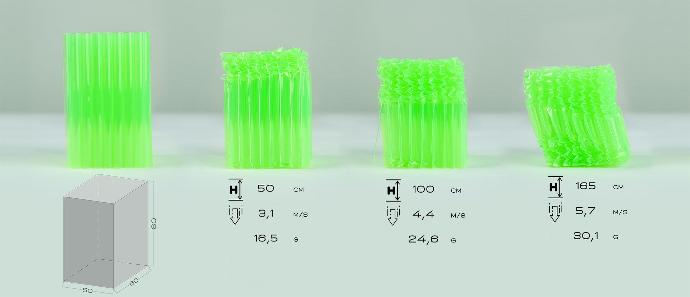

The dropping height is measured from the surface of impact to the lowest point of the test dummy and should not be lower than 165 cm.

-

For a value of 38 g, the top duration is 7 ms.

-

For a value of 20 g, the top duration is 25 ms.

PERFORMANCE OF NEO-KOROYD IN PARAGLIDING HARNESS PROTECTIONS

The impact energy associated to the EN1651 standard is of 809 J with a theoretical impact speed of 5.7m/s (20.5km/h). The role of energy absorption materials is to absorb a maximum of energy without becoming denser and transferring residual forces to the pilot.

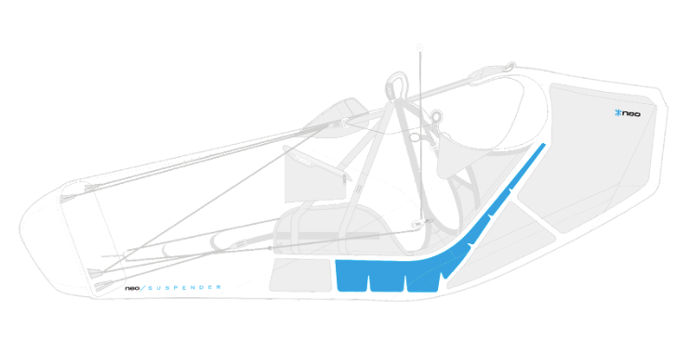

The Koroyd specification chosen for paragliding by NEO is the Koroyd HP60048. This specification has a cell diameter of 6.0mm and a density of 48 g/l. The size of the Koroyd inserts changes depending on the protection's reference.

The Koroyd is used together with a foam with a density of 24 kg/m3. The foam gives the overall shape to the protection and keeps the Koroyd inserts in place. It also gives some flexibility to the protection.

EFFICIENT DURING LIGHT IMPACTS

The tests show that the Koroyd inserts start deforming at a 30 cm drop (drop speed of 2.4 m/s). The impact energy is therefore absorbed even at a low intensity impact.

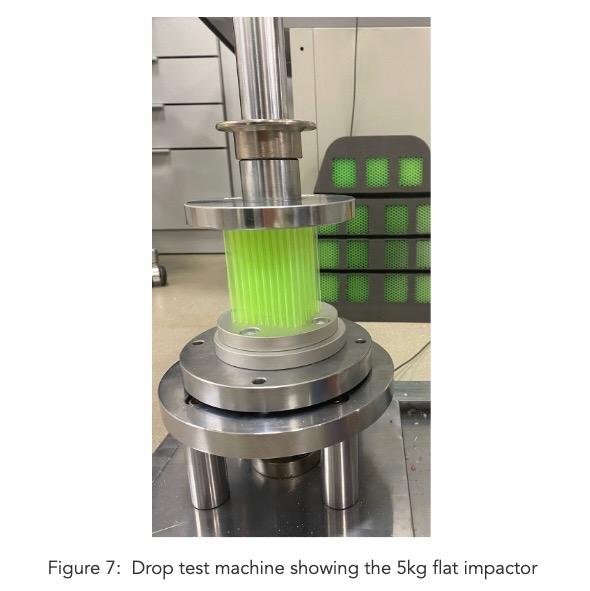

DYNAMIC TEST PERFORMANCE

Figure 8 shows the results at low and high impact heights according to the test procedure with a 50 kg dummy.

We tested the NEO-Koroyd 3.0 with the NEO Suspender harness at 0.5m, 1m, and the standard EN height of 1.65 m at the Air Turquoise laboratories in Villeneuve, Switzerland. The results show an efficient energy absorption from 50 cm and therefore, for low-speed falls.

THE BEHAVIOUR OF THE KOROYD

The graphic at the right side has been badly explained or misinterpreted. It is one of the main subjects of controversy concerning Koroyd in paragliding protection.

This graph is obtained during a laboratory test, the quasi-static test. This is a method used to characterise the damping properties of a material. Unlike a dynamic test, where the material is subjected to rapid loading and deformation, the quasi-static test involves the slow, controlled application of a force or deformation to the material. Although this test is not specifically designed to simulate dynamic shocks, it can provide useful information about a material's response to progressive loading. There is a link between the results of the quasi-static test and the performance in absorbing a mechanical shock.

Analysis of the stress-strain curve obtained during this test with the Koroyd shows:

1 - The ability to absorb a large amount of energy from the start of the impact

2 - Koroyd's capacity for plastic (non-reversible) deformation: this type of deformation helps to absorb energy in a controlled way during an impact.

3 - The ability to absorb stress using 70 to 80% of the thickness.

These characteristics, demonstrated by the quasi-static test, enabled us to choose Koroyd as a material with real potential for paragliding protection. Koroyd's performance was validated in a low-energy dynamic test and in the EN 1651 standard test.

TYPES OF NEO-KOROYD PROTECTIONS

IN PARAGLIDING HARNESSES

It is widely known that the body can withstand a strong acceleration for short periods of time. Efficient body protection devices minimize the acceleration with time.

NEO-KOROYD IN THE OZONE, GIN AND ADVANCE HARNESSES

The performance of the technologies developed by NEO and Koroyd have convinced other paragliding equipment brands to respond to the requirements of competition. NEO-Koroyd has been chosen byOzone, Gin and Advance, in the Ozone Submarine, Gin Genie Race 4 and 5 harnesses and the pro-model Advance harnesses used on the X-Alps.

FEEDBACK ON NEO-KOROYD

The technologies developed by NEO and Koroyd have convinced many pilots. Discover the opinions of some pilots who have been protected in a flight incident thanks to NEO-Koroyd :

"Dear Team Neo, I'm very grateful to fly with your superb harnesses: the NEO Shorty for the last three years and the NEO Suspender for the last two... as well as your Hexagon helmet... I'm particularly grateful to be able to speak to you today, as last March I was involved in a crash for reasons that still elude me. Shortly after take-off, I found myself on the ground and in hospital after undergoing surgery. Today, I can count myself fortunate that these inconsequential injuries were limited to the bones of the limbs and face, and that there were no spinal injuries, which often lead to serious after-effects. The damaged cubes of the Koroyd back protector on my Suspender 1.0, however, suggested that this integrity was not self-evident. I'm sure that the quality of your equipment is one of the main factors that enabled me to make a speedy recovery (recovery of mobility and no back or head injuries - the Hexagon helmet did its job too)!!!!

Thank you so much!!! All the best and keep up the good work."

Lukas, Austria

"I found myself in a tricky situation last August above Hauteluce. I was just finishing a beautiful flight when the thunderstorm arrived. I was caught short because it was coming from the Aravis, behind Bisane. So I only saw him at the last. Unfortunately too late, as the rain and turbulence soon came down on me and I was still perched high above Lac de la Girotte. I came down quickly enough to land, and just a few meters from the ground as I was making my last turn, my wing stalled. I fell a little more than 5 metres, leaning slightly to the right. The impact was quite violent, my knee hit my head, my teeth chattered, I've got a few muscle aches but nothing's broken, I'm fine. After all these emotions, I check the equipment, and in particular the protection of my Stay-up harness, which has played its role really well. A few squares are touched, and it's clear that despite the cross-fall, the protection was very effective. The affected squares are only partially crushed on one side, so you can imagine the direction of the impact quite well."

Olivier, France

"Dear NEO, I've been fooling around with my Stay-Up harness... I tested the protection in real conditions: verdict it protects very well! 👍 Thank you for this beautiful design!"

Claire, France

"The incident was caused by a failed take-off and a fall on the front of the take-off at Otivar in Spain. No injuries or damage to the harness, but the inserts did their job."

Nic, England

"Hi. I need to purchase some new honey comb tubes for my Gin Ginie Lite 3 seat area.. about 6 of them please.

To be honest, I had a fast fall straight down and they were amazing.. sure saved my back.. I was actually very, pleasantly surprised how good they were in a real life accident...

Thank you for your engineering knowledge ... Best regards "

Darren, UK

"Flying the coarse line into the Citusdal Valley (South Africa) over the Winterhoek Mountain range where I hit the expected sink , which normally ends about 1/2 across the valley . I aimed for a field in Sun , I recollect starting to thermal making several turns and feeling very chipper... my next memories are all rather broken... I have an image on my glider in a ball above me . The next are of being on the ground surrounded by various people and paramedics.

I’m unsure how long I was unconscious but my next memory was of 2 fabulous competition pilots whom had landed beside me and were helping me ( They were so helpful and reassuring ). I remember doing a primary survey on myself and assessed myself as having no obvious boney injuries ( I am a retired doctor ). I was able to walk to the ambulance...though memories very vague.

I was latter informed that there was witnessed several dust devils in the area... 2 pilots suffered deflations... 1 reserve was thrown another landed with a damaged wing. None of those pilots suffered injuries.

I was taken to the local hospital where my scalp laceration was sutured and was latter discharged .

On viewing my track log file I descended the last 30m vertically .

On viewing my track log file I descended the last 30m vertically. Thank you NEO, I walked away from the incident unhurt thanks to your system ❤️."

Doug, UK